Vertical Roll out Sheet Metal Rack

The Vertical Roll Out Sheet Metal Rack is a specialized storage system designed to organize and protect sheet metal and other flat materials efficiently. By storing sheets vertically on roll-out drawers, the system not only saves floor space but also makes individual panels easily visible and accessible. This design is particularly beneficial in industrial settings where quick material retrieval is essential, such as in metal fabrication, workshops, and manufacturing facilities. The vertical orientation minimizes the risk of bending or scratching, ensuring that each sheet remains in pristine condition until needed.

Specifications

While the exact specifications can vary between manufacturers and models, typical features include:

Capacity and Dimensions:

Standard load capacities range from around 400 kg per unit up to 1500 lbs (approximately 680 kg) per drawer, depending on design and intended use.

Models are available in multiple sizes (for example, sheet storage dimensions might range from 6′ x 4′ to 12′ x 5′ or customized to suit specific needs).

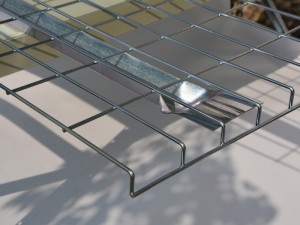

Drawer System:

The rack consists of multiple roll-out drawers or sliding units, often with non-skid surfaces that allow 100% extension for full sheet visibility.

The drawers are engineered to support various sheet sizes, including cut-offs, remnants, and partial sheets.

Construction Materials and Finish:

Typically constructed from heavy-duty steel (e.g., Q235) with durable surface treatments like powder coating or protective lining.

Customization Options:

Options such as wire mesh backing, removable holding arms, and adjustable drawer spacing can be tailored to meet unique storage or operational requirements.

Advantages

Vertical Roll Out Sheet Metal Racks offer several notable benefits:

Space Optimization:

The vertical configuration and compact design maximize storage density while freeing up valuable floor space for other operations.

Enhanced Visibility and Accessibility:

Each roll-out drawer provides a full view of its contents, reducing the time needed to locate specific sheets and minimizing handling errors.

Improved Safety:

By eliminating the need for heavy manual lifting or awkward retrieval methods, these racks help reduce workplace injuries.

The design minimizes risks of bending or damaging the sheets, contributing to a safer working environment.

Efficiency and Labor Savings:

Quick access to stored sheets leads to faster material handling and streamlined workflows, ultimately reducing operating costs.

Customization:

Flexible design options allow facilities to tailor the system to different sheet sizes, load requirements, and operational needs.

Usage Scenarios

Vertical Roll Out Sheet Metal Racks are particularly suited for:

Manufacturing and Fabrication:

Ideal for storing raw materials like metal, plywood, or plastic sheets in production lines where quick access is crucial.

Workshops and Metal Processing Facilities:

Helps organize cut-offs, remnants, and partial sheets to minimize waste and improve production efficiency.

Warehousing:

Optimizes space in storage areas, ensuring that materials are neatly arranged and easy to inventory.

Customized Storage Needs:

Suitable for facilities with specialized storage requirements, such as for delicate panels or irregularly sized sheets, where additional protective features (like slanted drawer surfaces to prevent slippage) are beneficial.

Facilities can also combine vertical systems with other storage solutions (like horizontal racks or cantilever systems) to create a comprehensive material handling strategy.

Conclusion

The Vertical Roll Out Sheet Metal Rack is an efficient and safe storage solution tailored for handling sheet materials. Its roll-out design, robust construction, and customizable options make it an attractive choice for industries that demand quick, reliable access to their materials while maintaining a compact footprint. Whether used in high-volume manufacturing or specialized fabrication, this system offers a practical and cost-effective solution for modern storage challenges.

Feel free to reach out to a specialist for tailored recommendations and further details on customizing your storage system.