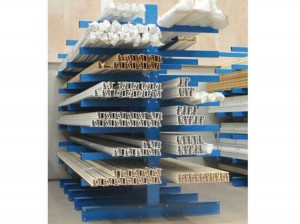

High Density Double Pallet Racking Systems

High-density double-deep pallet racking is a last-in, first-out (LIFO) system. This type of racking reduces the number of accessible stock keeping units (SKUs) since 50% of the SKUs are behind the pallets when the storage location is full. Depending on the racking layout, the pallet storage capacity can be increased by up to 10-15%.

Double deep is better suited for inventory with medium to long term shelf life. Due to the LIFO shelving type, highly perishable goods are not recommended for this type of storage.

Advantages and disadvantages of double-deep racking

Advantages

● Increased storage capacity compared to selective racking

● Medium to low storage system.

● Depending on the racking layout, pallet storage capacity can be increased by up to 10-15%.

Disadvantages

● Reduced SKU accessibility

●Last-in, first-out inventory management.

● Requires special trucks.

Applications.

● High-capacity SKU storage

● Limited space

● Combination of selective and high density pallet racking for lower cost